Tag: Silkwood

Distaff

Wrist Distaff – used to wrap roving on, so that the roving is kept out of the way when using a drop spindle. The leather strap and bead go on the wrist. A one inch measure at the top of the staff allows for wraps per inch to be calculated for yarn produced.

Staff made from Silver Beech. Bead made from Silkwood. Leather strap and stainless steel eye screw. Finished with Tung Oil, Shellac and Beeswax.

Necklace – hei matau

The fish hook shape of the hei matau has origins in Māori legend, which tells of Te Ika a Maui, a huge fish that was caught by the great mariner using only a woven line and a hook made from the jawbone of his grandmother.

For the Māori, the hei matau is taonga (a cultural treasure). It represents not only their land, but also prosperity, fertility and safe passage over water.

Handmade necklace from curly grain Silkwood (Flindersia brayleyana) and leather. Finished with shellac, carnauba wax and beeswax.

Spoon Carving Knife Handles

I am selling quite a few spoons and scoops now, so it’s time to upgrade my spoon carving knife. I recently read a post recommending blades from Hillbilly Forge that were for sale at creativeman.com.au so a new tool project begins.

Basic Steps

Selecting some blades

I’d been considering purchasing a better quality spoon carving knife for a while, so when I saw a post on some Australian made blades I took the plunge. It’s cheaper to buy good quality blades and put handles on them then it is to buy a basic Mora spoon knife. Constructing your own tools makes those tools better – try it, you’ll see 😉

The blades come as a set of two, made from 1095 high-carbon tool steel, hand made by Jason at Hillbilly Forge in New South Wales, Australia.

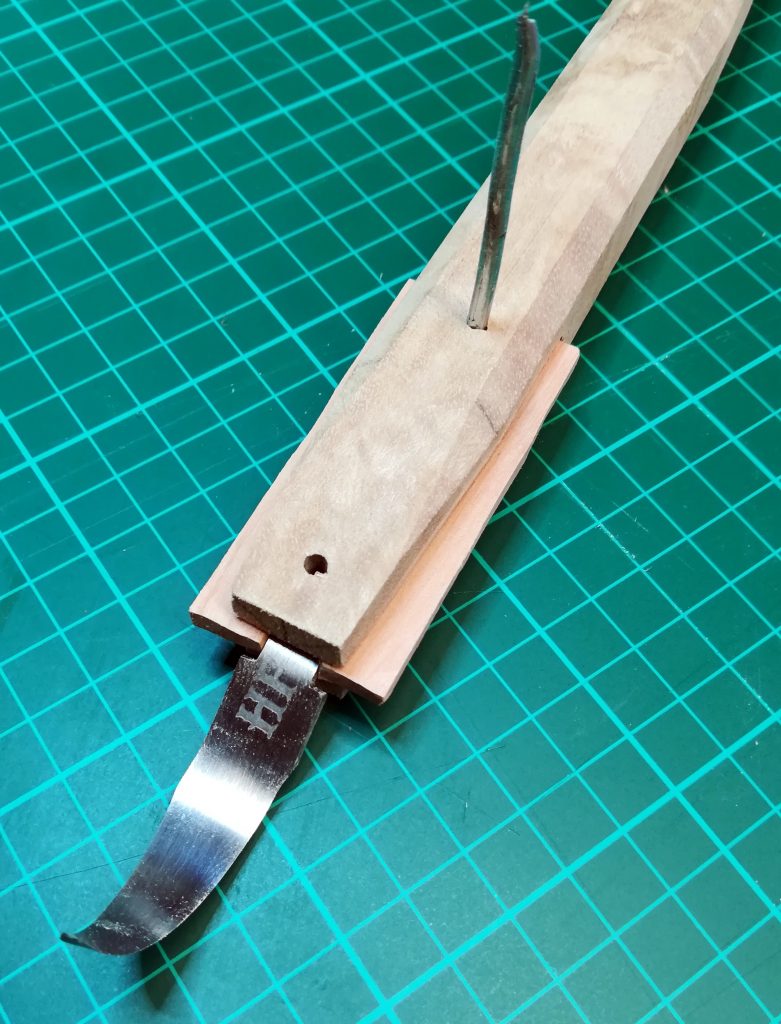

These blades have holes for pins, which will be added for extra strength. Some surface rust indicates the high carbon content. Not shown, but the rust was removed before glue up.

The blades are flat on the inside and beveled on the outside. An etched forgers mark is a nice touch.

Layout

Some very nice Queensland Maple was selected for the handles. Length of handles is a little over 200mm (8 inches) to allow for more gripping power and some different hold techniques. My current knife has a short, fairly flat handle and I don’t find it very comfortable to hold.

Basic Shaping and Glue Up

Some basic shaping was added to the handle before glue up. I like the more square shaped handle that should provide extra grip. Holes were added for the pins and some Totara (local NZ timber) was used for the blade tang fillers for the first knife.

The tang fillers were glued using wood glue first. This allowed the blade to still slip in and out. When dry, the handle was shaped a little more, and the excess tang fillers were removed. The top section of the handle was wrapped with masking tape to keep the epoxy off the handle and to cover the pin holes so the epoxy didn’t run out. Epoxy was poured into the hole and the blade was pushed in. Once the blade was in position the pins were tapped into place and then the epoxy was left to dry.

Finishing Off

When the epoxy was set, the excess pin ends were cut off using a hacksaw. A metal file was used to file down and smooth the pin ends. The masking tape was removed followed by an all over sanding. Tung oil was then applied liberally, which brought out the beautiful grain. I’m very pleased with the end result. The grip provided by the square shape is much better and the length feels perfect.

A beech tang filler was used for the second knife so they can be more easily told apart.

Done

Now to make some wooden sheaths…